Your Location:Home > Products > Organic chemicals

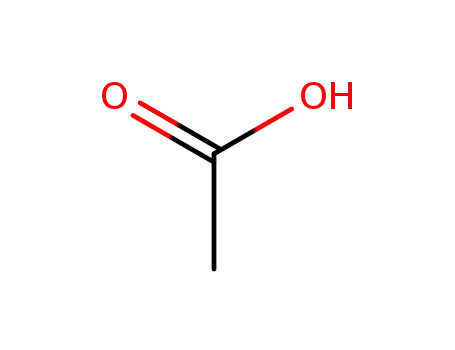

CasNo: 57-08-9

MF: C8H15 N O3

Appearance: White.

|

Manufacturing Process |

400 L of demineralized water, 5.0 kg of calcium hydroxide, and 155.0 kg (1000 moles) of acetyl-caprolactame are introduced under stirring and at a temperature of about 25°C into a 1000 L stainless double walled reactor. The temperature is raised to 30°C. 75.0 kg of calcium hydroxide are introduced stepwise in the form of successive amounts of 2.0 kg each in the medium, under stirring and at a temperature adjusted and maintained 25°- 30°C through external cooling, in a manner such that the time required to introduce into the reactor the whole amount of calcium hydroxide approximates 1.5 h. When the stirring is stopped, the pH is about 7.5-7.8. The obtained mixture is stirred continuously at a temperature of 30°C during 14 h. At the end of this operation the pH is again adjusted at a value 7.5-7.8. The hydrolysate is filtered on a 60 x 60 pressfilter comprising 6 compartments and equipped with fabrics of the polyester known under the designation TERGAL which have been previously coated with a suspension of a cellulose commercialized under the trademark SOLKA FLOX BW20. The duration of filtration is of 1.5 h. 580 L of the filtrate are recovered and subjected to a concentration under reduced pressure in an evaporator the volume of which is of 750 L, at a distillation temperature ranging from 45°-50°C under a reduced pressure of 10-15 Torr. The operation is ran until concentration of the solution to 280 L, the concentrated solution being then left standing. The crystallisation is already considerable 2 h after the end of the operation of concentration. Crystallisation is ended after 16-24 h. The crystals are centrifuged at a speed of 700 revolutions/minute. The centrifuged crystals of calcium acexamate are washed twice on the centrifuge with 20 l of acetone. 107.0 kg of crystals are obtained, which are dried under vacuum at 40°C. The 96.0 kg of dry calcium acexamate obtained are ground and sifted. Acexamic acid may be produced by treatment of the calcium acexamate with HCl. |

|

Therapeutic Function |

Antifibrinolytic |

InChI:InChI=1/C8H15NO3/c1-7(10)9-6-4-2-3-5-8(11)12/h2-6H2,1H3,(H,9,10)(H,11,12)/p-1

Human serum albumin has been specificall...

Friedel-Crafts acylation of ferrocene wi...

The present disclosure relates to imagin...

Amine dehydrogenases (AmDHs) catalyse th...

The invention discloses a method for syn...

The acidity of N-acyl amino acids is dep...

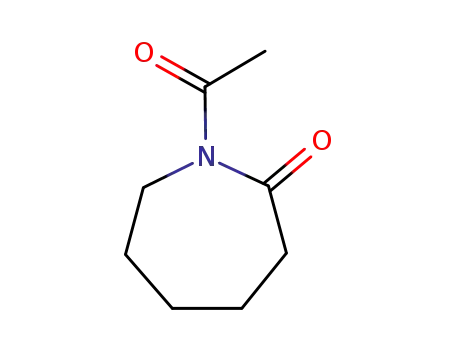

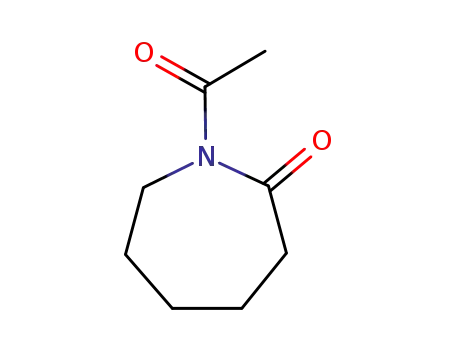

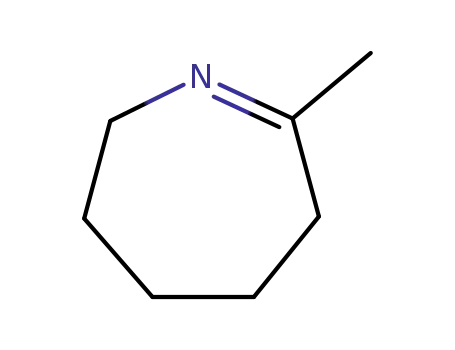

N-acetylcaprolactam

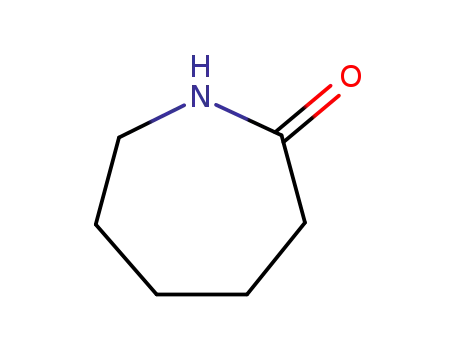

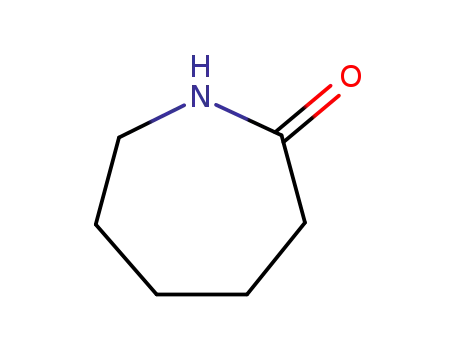

caprolactam

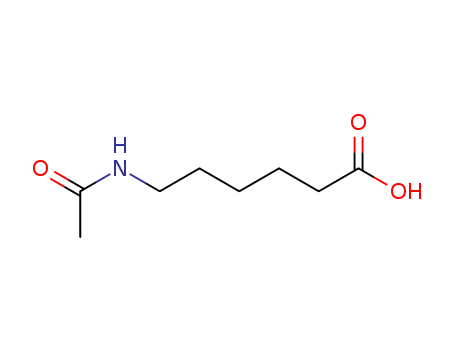

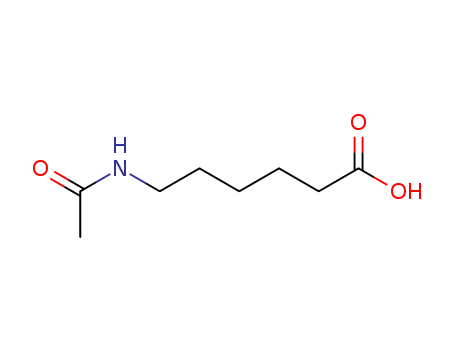

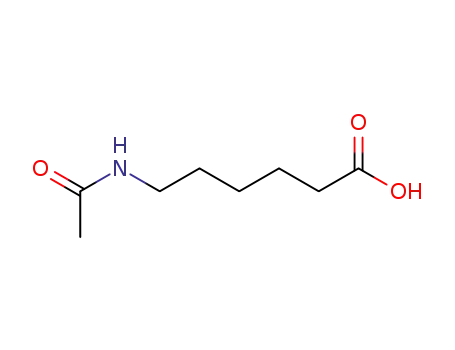

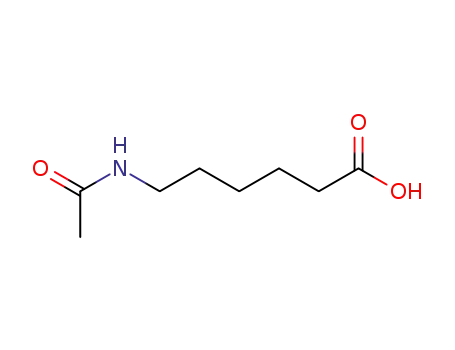

6-(acetylamino)hexanoic acid

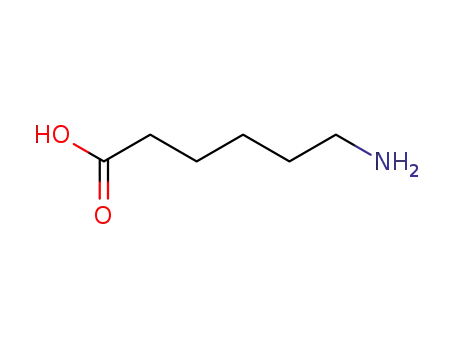

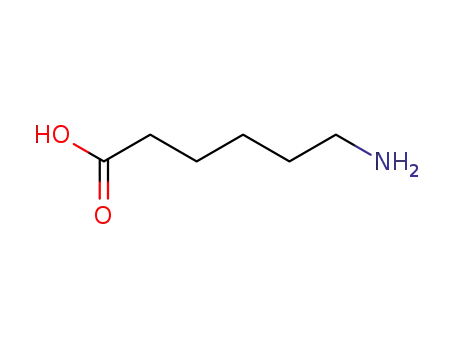

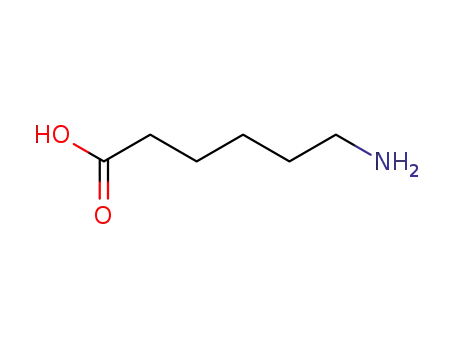

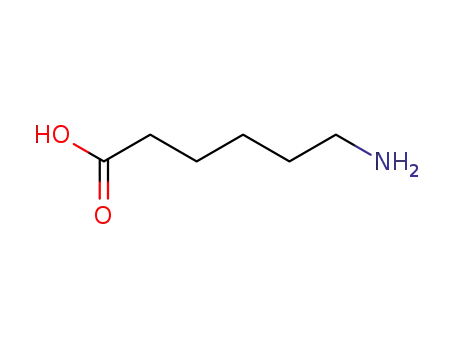

6-aminohexanoic acid

| Conditions | Yield |

|---|---|

|

With

water;

at 100 ℃;

Product distribution;

different time of hydrolysis;

|

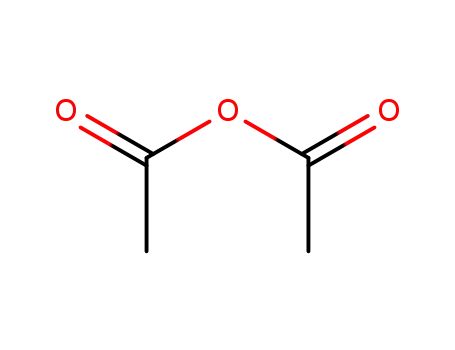

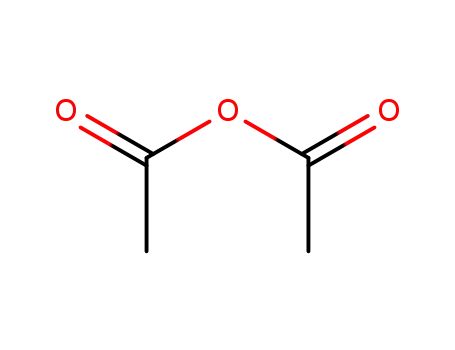

acetic anhydride

6-aminohexanoic acid

6-(acetylamino)hexanoic acid

| Conditions | Yield |

|---|---|

|

With

N-ethyl-N,N-diisopropylamine;

In

N,N-dimethyl-formamide;

at 0 - 20 ℃;

|

79% |

|

With

pyridine;

In

benzene;

|

|

|

In

dichloromethane;

for 0.5h;

|

|

|

With

dmap;

at 20 ℃;

for 0.5h;

|

N-acetylcaprolactam

acetic anhydride

6-aminohexanoic acid

acetic acid

2-methyl-4,5,6,7-tetrahydro-3H-azepine

caprolactam

6-aminohexanoic acid

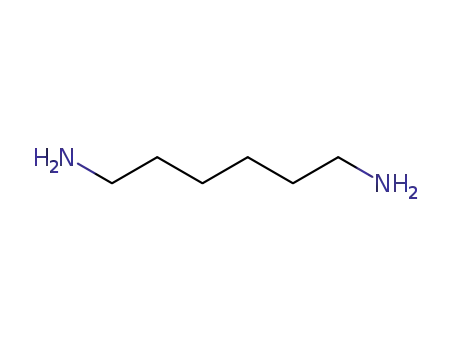

1,6-Hexanediamine